Research Topics

Gas Flows

Gas Flows

Dynamics of confined flows: velocity slip and temperature jump at the wall

Gas flows in micro systems (gas-micro-flows) are of great interest for various applications that touch almost every industrial field, such microheat exchangers, pressure gauges, fluidic microactuators for active control of aerodynamic flows, mass flow and temperature microsensors, micropumps, and microsystems for mixing or separation for local gas analysis, mass spectrometers, vacuum, and dosing valve.

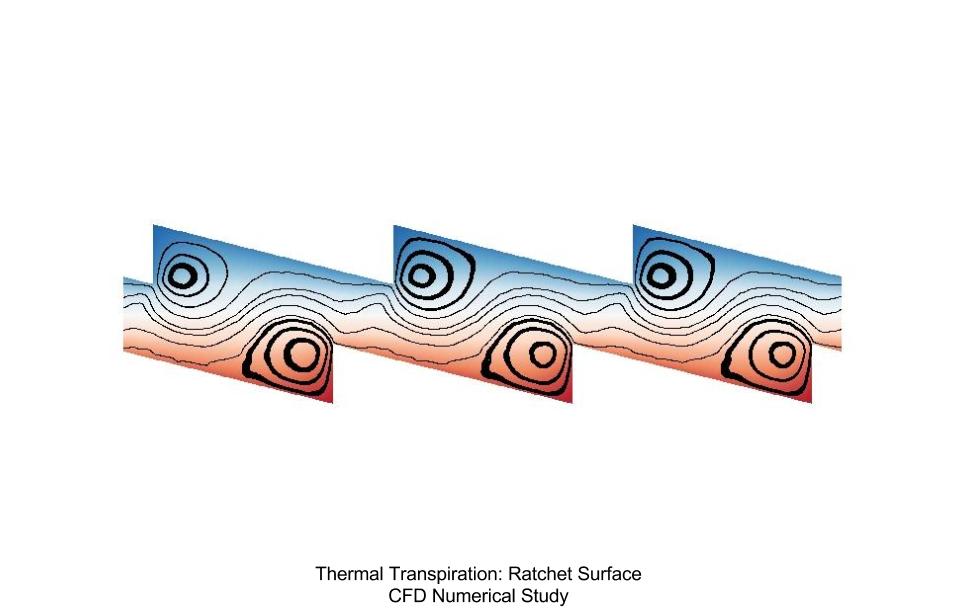

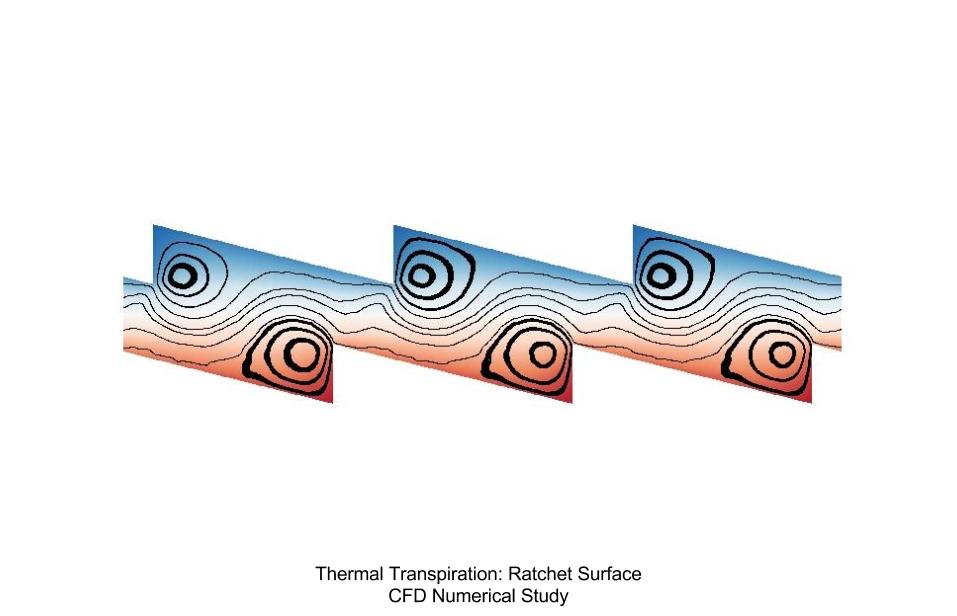

Thermally driven flows: thermal transpiration

Thermal transpiration refers to the macroscopic movement in a rarefi ed gas induced by a temperature gradient distributed along the solid surface bounding the fluid. The gas moves in the temperature gradient direction, from the lower to the higher temperature zone. This phenomenon is known as thermal creep or thermal slip at the wall, too.

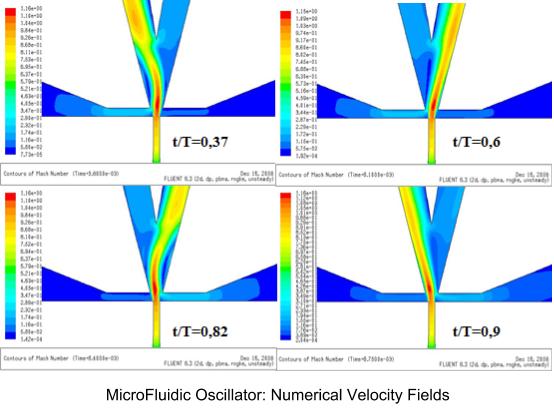

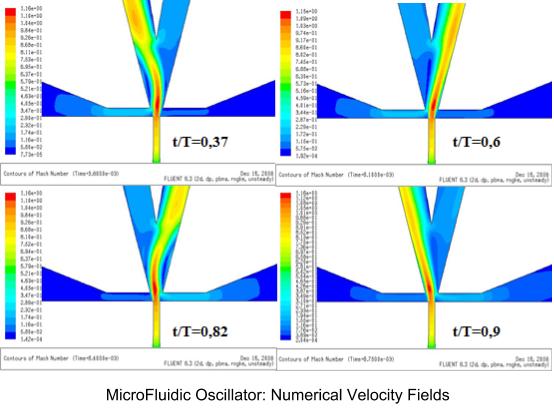

Micro-actuators for flow control

Wall-bounded flows may be efficiently controlled by appropriately modifying the boundary layer structure. It is thus possible to reduce the drag or increase the lift of an aircraft wing, to favor mixing in a combustion chamber, to reduce the aero-acoustic noise, or to improve heat transfer. The nature of perturbations that need to be introduced in the boundary layer mainly depends on the flow characteristics: Reynolds and Mach numbers, type of instabilities in the boundary layer, etc. For high Reynolds numbers and for compressible flows, active control methods, based on local momentum injection in the near wall flow thanks to dynamic systems composed of sensors and actuators, have proven to be efficient in particular for flow separation control.

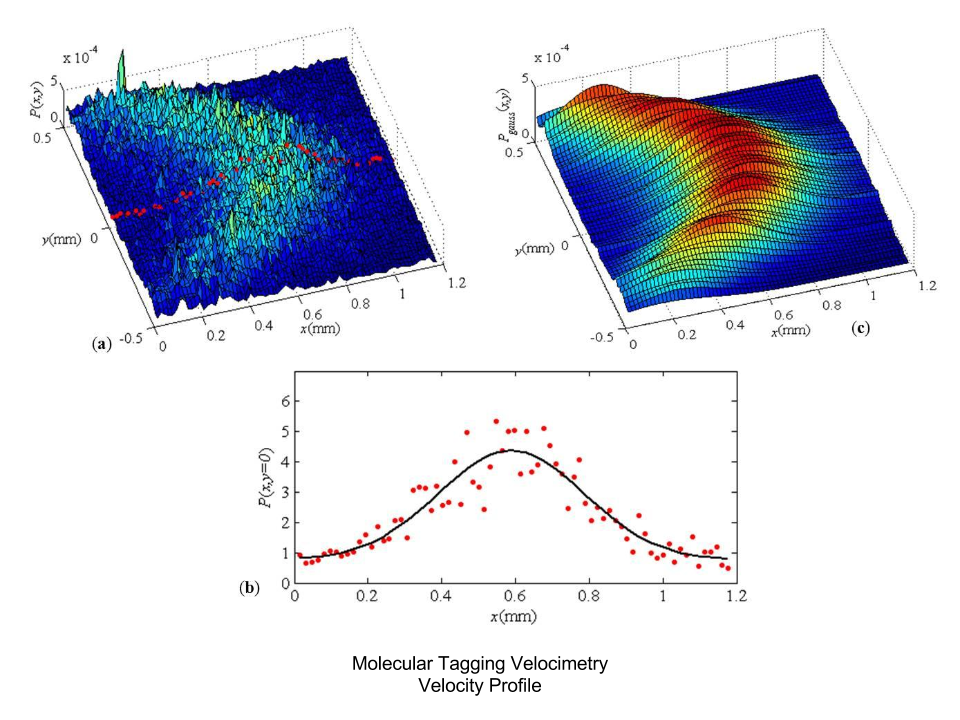

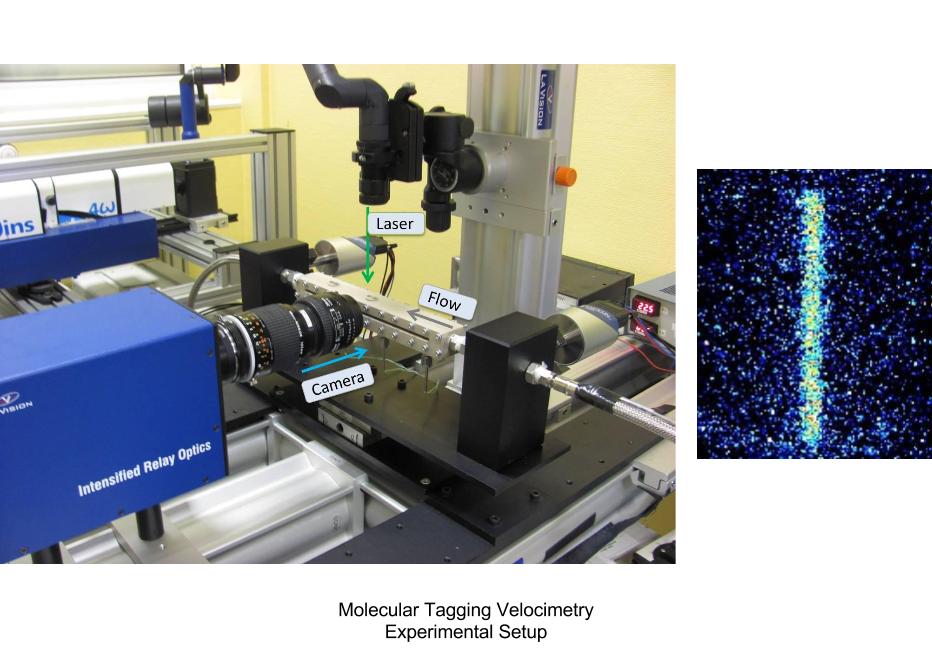

Molecular Tagging Velocimetry in confined flows

A new micro molecular tagging velocimetry (μMTV) setup has been developed to analyze velocity fields in confined internal gas flows. MTV is a little-intrusive velocimetry technique. It relies on the properties of molecular tracers which can experience relatively long lifetime luminescence once excited by a laser beam with an appropriate wavelength. The technique has been validated for acetone seeded flows of argon inside a 1 mm depth rectangular minichannel.

Liquid Flows

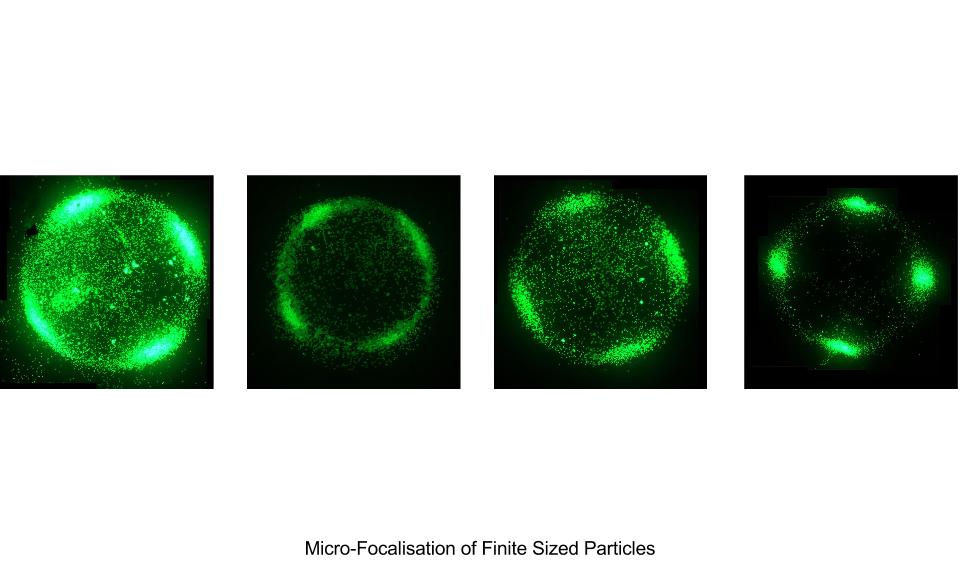

Micro-Focalisation of Finite Sized Particles

In the last decade, the particle migration due to flow inertia has been extensively used for successful particle separation and sorting in microfluidic devices. Square channels are often considered due to the ease of their manufacturing process. However, it is complex to establish theoretical predictions of the particle-flow interaction in rectangular 3D flow geometries. At finite inertia, the experiments and numerical simulations agree on the fact that, in a square channel flow, particles first undergo a cross-streamline migration (similarly to the Segré-Silberberg phenomenon) until they reach an equilibrium ring parallel to the velocity iso-contours.

Two Phase Flows

Bubble Image Velocimetry for the Characterization of Medical Micro Pumps

An experimental setup for the accurate measurement of micro-flowrates delivered by medical micropumps has been developed. It is based on the air bubble tracking method and permits measurements of both mean and instantaneous flowrates, which is necessary for evaluating the performance of pulsed micropumps.

The typical measured flowrates are in the range of 2.5 10^-13 m^3/s to 2.5 10^-10 m^3/s with an uncertainty of +/- 4% . Two methods of measurement are used simultaneously:

- The first is based on bubble tracking: an air bubble is pushed by the liquid flow inside a calibrated glass pipette. The flowrate can be deduced from the time interval between the detection of the bubble with two optical sensors mounted on the pipette. This gives a mean flowrate, the pipette volume between the two sensors being 5μl.

- The second method consists in deducing a flowrate from image analysis. Images of the air bubble are registered by a video camera, the comparison between two successive images in the sequence allows one to obtain the displacement of the bubble inside the pipette and, given the acquisition frequency, and the instantaneous flow rate.

All the data are recorded with a PC acquisition system and analyzed using specific software.